Volumetric Measurement in Cutting Machines via 2D/3D Profile Sensors

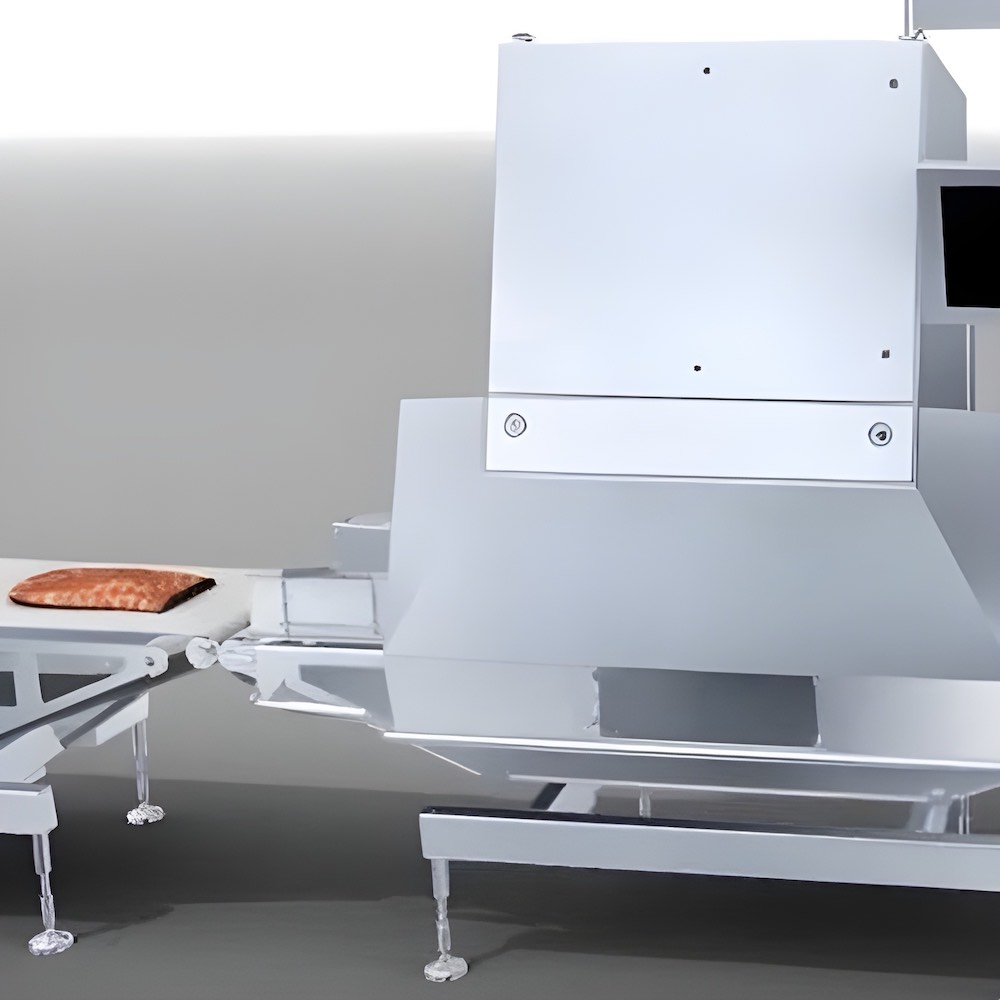

To guarantee consistent packaging, each food portion must meet the declared weight, never less. This involves measuring products like cheese or meats to calculate their exact volume.

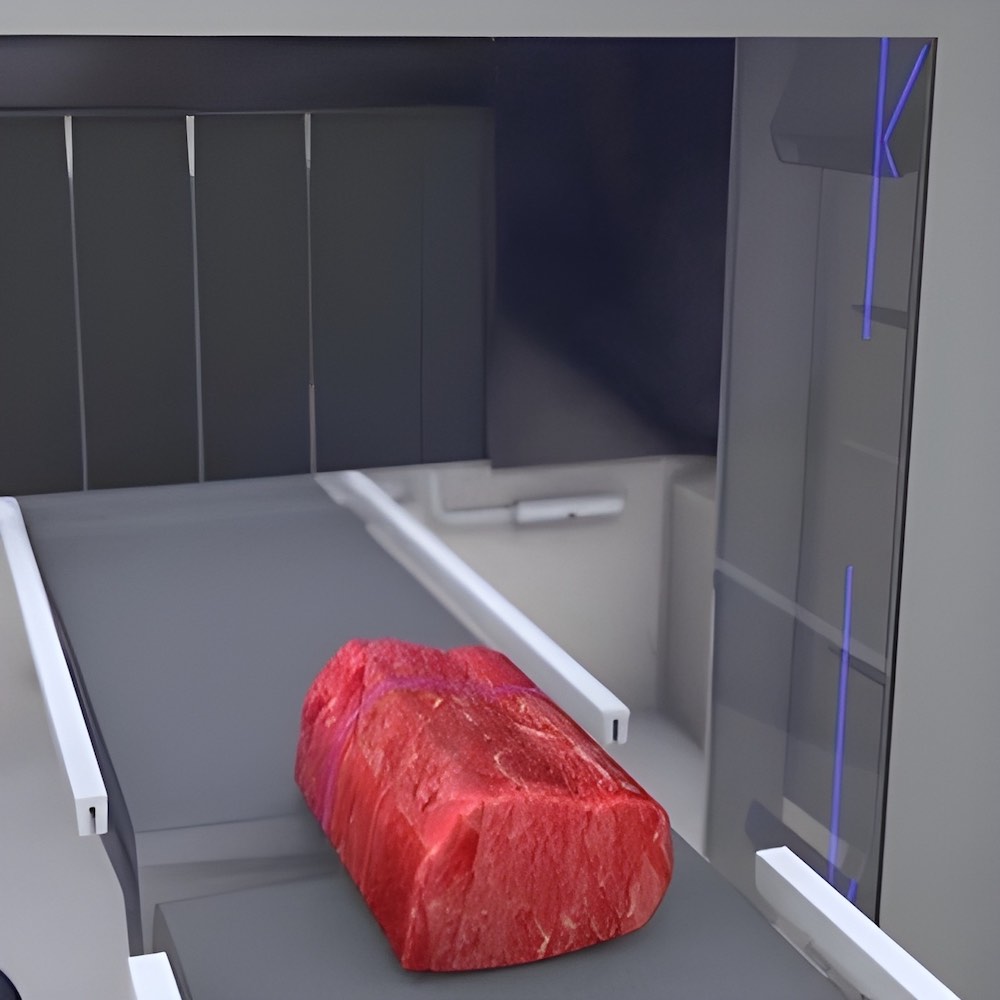

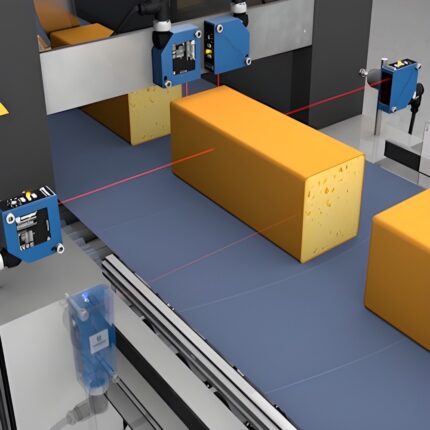

When packing food, it is important to ensure that the same weight is always packed per unit – but never less than stated. Cheese, meat or sausage products must therefore be measured in order to calculate their exact volume. Four 2D/3D profile sensors with a red or blue laser line detect the organic objects via triangulation and create 2D height profiles.

These are then combined and evaluated via image processing software and the data could be transferred using TCP-IP, UDP, Ethercat or other communication protocol. The frequency, the thickness and the weight of the slicing of portions is calculated from this volume data and product length and height.

Example of products we are able to detect: