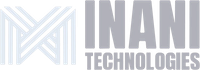

Measuring Blocks of Cheese with Triangulation Laser Distance Sensors for Controlling Cutting Machines

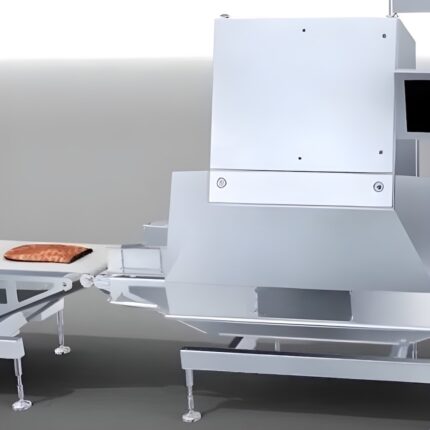

In the food industry, it is important to accurately measure blocks of cheese on conveyors before cutting. This enables the amount of waste to be significantly reduced when the blocks are subsequently cut.

In the food industry, it is important to accurately measure blocks of cheese on conveyors before cutting. This enables the amount of waste to be significantly reduced when the blocks are subsequently cut.

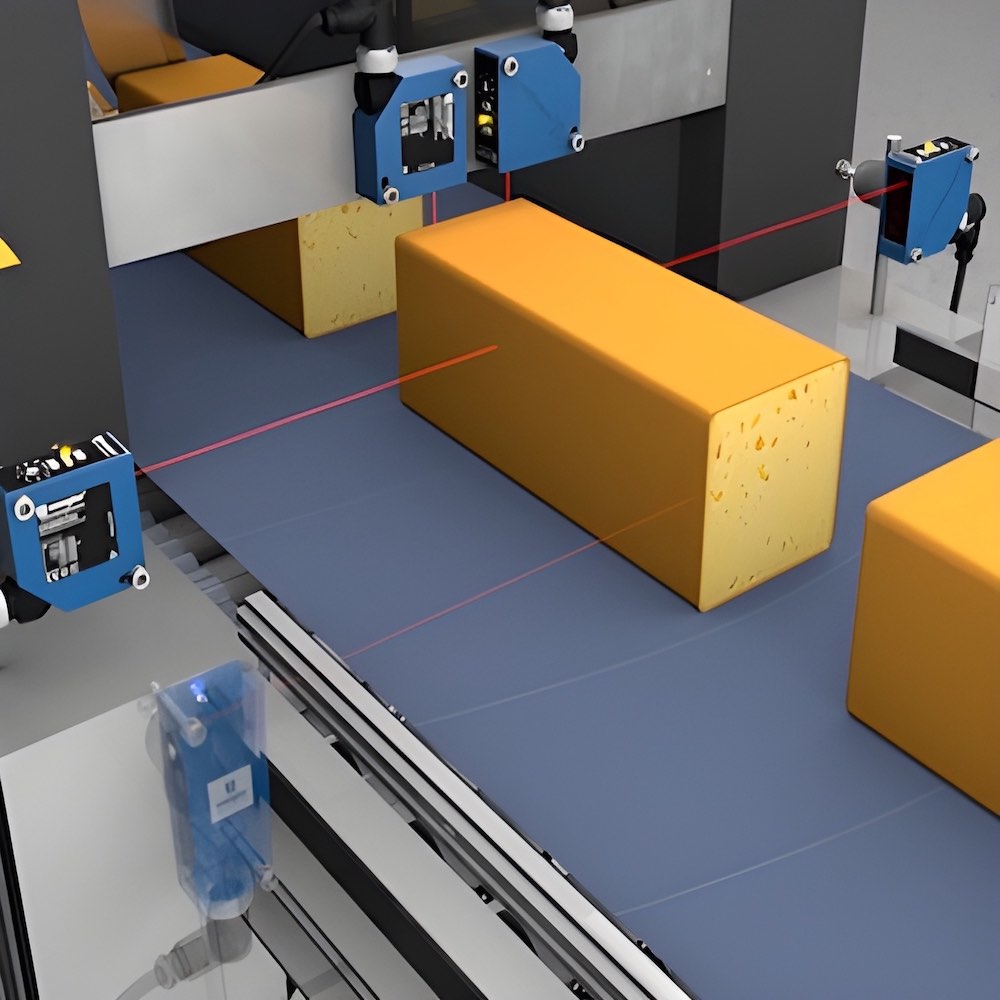

To this end, two triangulation laser distance sensors are installed above and one on each side. The analog measurements can be used to calculate the volume of the cheese and thus determine the ideal frequency of the cutting knife.

To avoid keeping the measuring sensors permanently in operation, a retro-reflex sensor is installed upstream as a trigger – this saves electricity and therefore costs.