Expert Services

From Setup to Performance

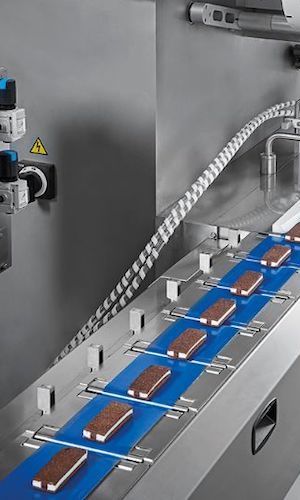

Offering comprehensive service solutions, we enhance performance and efficiency at every stage of your plant's life cycle, ensuring lasting impact beyond routine maintenance and maximizing value.

Optimizing Performance With Smart Services

Our services are built on quality, innovation, and value, extending far beyond equipment maintenance. We work closely with you to improve availability, efficiency, and sustainability through digital transformation.

Together, we create solutions that drive measurable business growth, ensuring long-term reliability and efficiency in every service we provide.

Enduring Growth

Through Reliable Service

We provide advanced services from initial advice to installation, ensuring maximum availability throughout the lifespan. Our support covers every stage, from setup to performance.

UPTIME PERFORMANCE

Prioritize high availability through strategic maintenance and technology, ensuring continuous, efficient, and smooth production operations.

AFTER-SALES SUPPORT

Provide instant solutions, expert support, and reliable assistance to resolve issues quickly and keep your processing line running smoothly.

STRATEGIC UPGRADES

Maximize efficiency and quality with targeted upgrades, bringing your production lines to the next level in performance and hygiene.

Proactive Support For Seamless Workflow

We offer proactive technical support with quick and reliable issue resolution to minimize downtime. Trust us for expert service, tailored guidance, and continuous reliability.

Empower Workforce

With Advanced Knowledge

Advance team expertise with expert training and in-depth knowledge, keeping them skilled, informed, and ready to drive efficiency, innovation, productivity, and long-term success forward.

Proactive Maintenance

Optimize system performance and ensure seamless production with expert automation training.

Automation Systems Operation

- Hands-on equipment operation and troubleshooting techniques.

- Preventative maintenance practices to reduce downtime.

- System diagnostics for quick fault identification.

Machine Potential

Enhance your production line’s efficiency and optimize your smart systems with high precision.

Machine Programming And Integration

- Customized programming for specific production needs.

- Integration of robotic systems with production lines.

- Training on software tools for optimization.

Standards & Regulations

Achieve global compliance with industry-specific training and ensure production quality and safety.

Industry Compliance And Regulatory

- Detailed knowledge of GMP, FDA, ISO standards.

- Training on food safety and pharmaceutical guidelines.

- Compliance audits and regulatory documentation practices.

Diagnostic & Repair

We don’t just provide technology; we support businesses throughout their automation journey.

Troubleshooting And Problem Solving

- Real-time diagnostics for machine-related issues.

- Step-by-step troubleshooting techniques for automation.

- Preventing future issues through root cause analysis.

Sustainable Practices

Reduce waste and save energy with sustainable practices for smarter automation solutions.

Sustainability And Energy Efficiency

- Energy-efficient production techniques and machinery.

- Strategies for reducing waste during production.

- Sustainable material sourcing and eco-friendly packaging.

Assistance & Support

Learn the latest automation technologies and unlock new potential with new industry tools.

Technology Updates And Advancements

As technology in automation evolves, INANI Technologies provides continuous training updates. This ensures that employees stay on top of the latest trends in automation, artificial intelligence, and data-driven performance metrics.

- Training on the latest automation software tools.

- Introduction to artificial intelligence in production.

- Adapting systems to new technological advancements.